Back to top

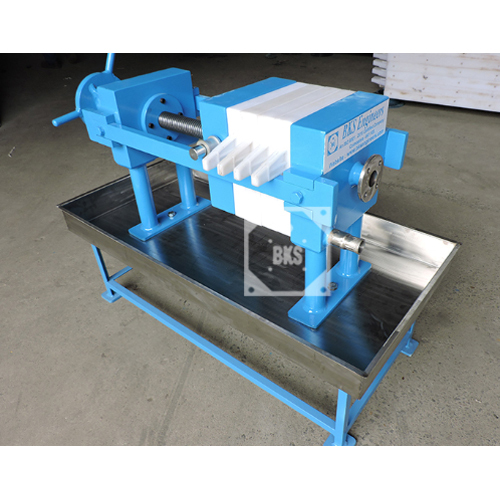

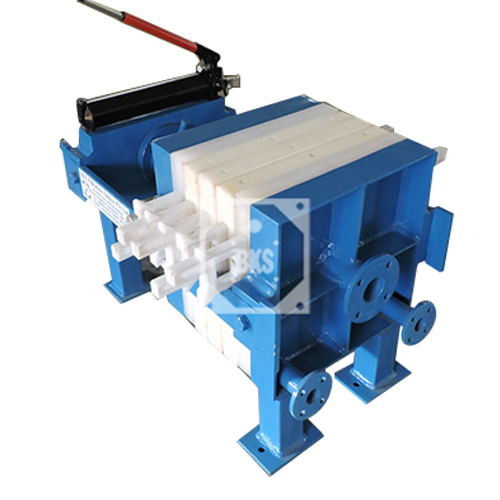

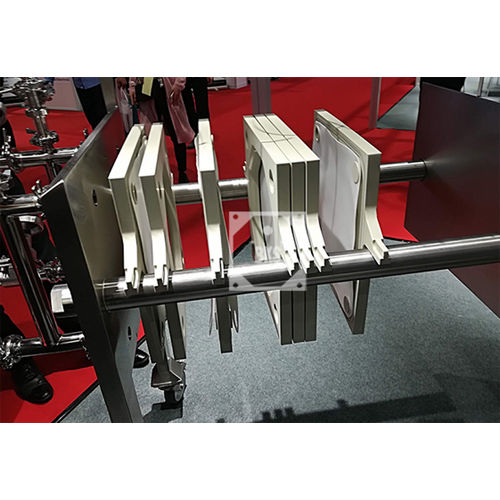

With excellence in business, we are the leading manufacturer of Filter Press.

BKS Engineers has been able to make a big name for itself in the market because of the commitment made to our customers to stand by us through thick and thin. Achieving maximum client satisfaction has always been the primary objective of our company, and we work hard for the same. We follow stringent quality-checking procedures to maintain the quality standards of our products. From product planning to designing and production to quality checking, everything is done in-house by taking all the necessary precautions.

Therefore, we are looked upon as a reliable manufacturer and supplier of premium-quality Roller Conveyors, Bottom Loading Wax Press Machines, Oil Filter Press Machines, Filter Press Feed Pumps, etc. By following in the footsteps of our CEO, Mr. V. Babbu, we have been abiding by all the rules and regulations of the industry. Thus, winning the hearts of a wide customer base spread across the whole nation.

Therefore, we are looked upon as a reliable manufacturer and supplier of premium-quality Roller Conveyors, Bottom Loading Wax Press Machines, Oil Filter Press Machines, Filter Press Feed Pumps, etc. By following in the footsteps of our CEO, Mr. V. Babbu, we have been abiding by all the rules and regulations of the industry. Thus, winning the hearts of a wide customer base spread across the whole nation.

Send Inquiry

Send Inquiry Send SMS

Send SMS